Friction Stir Welding of Dissimilar Alloys and Materials: A Comprehensive Guide

to Friction Stir Welding

Friction Stir Welding (FSW) has revolutionized the welding industry by providing a unique and highly effective method for joining dissimilar alloys and materials. Unlike traditional welding techniques, FSW utilizes a rotating tool to create a solid-state bond between the materials, eliminating the need for high heat inputs and minimizing material distortion. This innovative technology offers numerous advantages, including:

- Excellent weld quality with minimal defects

- Reduced heat-induced distortion and residual stresses

- Increased joint strength and toughness

- Ability to join a wide range of alloys and materials, including dissimilar combinations

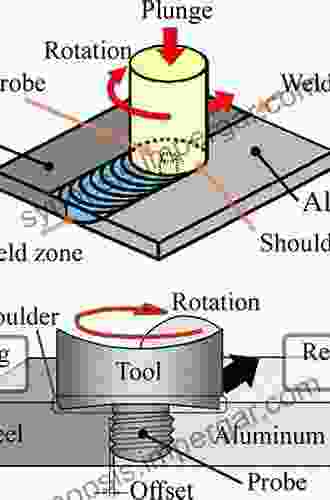

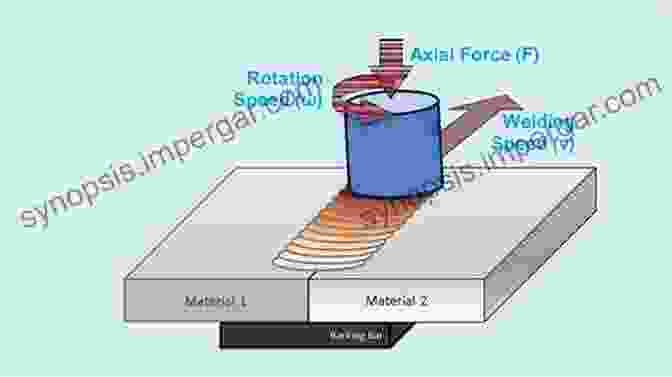

Principles of Friction Stir Welding

FSW operates on the principle of frictional heat generation and material stirring. A rotating tool, typically made of a hard material such as tungsten carbide, is plunged into the interface between the materials. The frictional contact between the tool and the workpiece generates heat, which plasticizes the material but does not melt it. The rotating tool then stirs the plasticized material, creating a solid-state bond. The tool traverse motion along the joint line produces a continuous weld.

5 out of 5

| Language | : | English |

| File size | : | 7489 KB |

| Text-to-Speech | : | Enabled |

| Screen Reader | : | Supported |

| Enhanced typesetting | : | Enabled |

| Print length | : | 134 pages |

Applications of Friction Stir Welding

FSW finds applications in a wide range of industries, including:

- Automotive

- Aerospace

- Shipbuilding

- Railway

- Construction

Specific applications include:

- Joining dissimilar aluminum alloys in aircraft structures

- Welding steel and aluminum in automotive body panels

- Fabricating lightweight composite materials in marine vessels

- Repairing damaged pipelines in oil and gas industry

- Creating complex geometric structures in architectural applications

Benefits of Friction Stir Welding

FSW offers several key benefits over traditional welding techniques:

- Solid-State Bonding: FSW creates a strong and reliable bond without the use of filler materials or melting, ensuring a high-quality weld with minimal defects.

- Reduced Heat Input: FSW generates less heat than other welding processes, resulting in reduced distortion and residual stresses, preserving the integrity of the materials.

- Enhanced Joint Strength: FSW produces welds with excellent strength and toughness, comparable to or even exceeding the base materials, ensuring the durability and reliability of the joint.

- Versatility: FSW can join a wide range of alloys and materials, including dissimilar combinations, providing greater flexibility in design and manufacturing.

- Increased Productivity: FSW offers higher welding speeds and automation capabilities, leading to increased productivity and reduced manufacturing costs.

Challenges and Future Directions of Friction Stir Welding

Despite its numerous advantages, FSW also presents some challenges:

- Tool Wear: The FSW tool experiences high wear due to the frictional contact with the workpiece, requiring frequent tool changes and maintenance.

- Material Compatibility: FSW is not suitable for all materials, and certain combinations may require specialized tool designs and process parameters.

- Joint Design: The geometry of the joint can influence the weld quality and strength, requiring careful design considerations.

Ongoing research and development efforts are focused on addressing these challenges and expanding the applications of FSW. Some promising directions include:

- Development of advanced tool materials and coatings to improve wear resistance

- Exploration of hybrid FSW techniques combining FSW with other welding processes

- Investigation of new materials and material combinations for FSW

- Optimization of FSW parameters and process control for enhanced weld quality and efficiency

Friction Stir Welding (FSW) is a revolutionary welding technology that has transformed the way we join dissimilar alloys and materials. Its unique solid-state bonding mechanism, reduced heat input, and enhanced joint strength offer numerous advantages over traditional welding techniques. With its versatility and wide range of applications, FSW is poised to play a vital role in shaping the future of manufacturing and engineering.

5 out of 5

| Language | : | English |

| File size | : | 7489 KB |

| Text-to-Speech | : | Enabled |

| Screen Reader | : | Supported |

| Enhanced typesetting | : | Enabled |

| Print length | : | 134 pages |

Do you want to contribute by writing guest posts on this blog?

Please contact us and send us a resume of previous articles that you have written.

Book

Book Novel

Novel Page

Page Chapter

Chapter Text

Text Story

Story Genre

Genre Reader

Reader Library

Library Paperback

Paperback E-book

E-book Magazine

Magazine Newspaper

Newspaper Paragraph

Paragraph Sentence

Sentence Bookmark

Bookmark Shelf

Shelf Glossary

Glossary Bibliography

Bibliography Foreword

Foreword Preface

Preface Synopsis

Synopsis Annotation

Annotation Footnote

Footnote Manuscript

Manuscript Scroll

Scroll Codex

Codex Tome

Tome Bestseller

Bestseller Classics

Classics Library card

Library card Narrative

Narrative Biography

Biography Autobiography

Autobiography Memoir

Memoir Reference

Reference Encyclopedia

Encyclopedia Dean Lorey

Dean Lorey Rod Pyle

Rod Pyle Tryambak Chatterjee

Tryambak Chatterjee Deborah Tannen

Deborah Tannen Mark W Cornwall

Mark W Cornwall David Murphy

David Murphy Joseph Ledoux

Joseph Ledoux Shirley A Jones

Shirley A Jones Deborah Niemann

Deborah Niemann David Nasaw

David Nasaw Doug Stebleton

Doug Stebleton Karen Alpert

Karen Alpert Kimberly K Arcand

Kimberly K Arcand Mary Carol Garrity

Mary Carol Garrity David M Ward

David M Ward Evelyn Abbott

Evelyn Abbott Denera Mccullough

Denera Mccullough Diane Ravitch

Diane Ravitch Frank Moore

Frank Moore Davina Florina

Davina Florina

Light bulbAdvertise smarter! Our strategic ad space ensures maximum exposure. Reserve your spot today!

Bret MitchellEssential Human Development Essentials: A Blueprint for Personal Growth and...

Bret MitchellEssential Human Development Essentials: A Blueprint for Personal Growth and...

Giovanni MitchellSkinheads 1979-1984: The Definitive Photographic Record by Derek Ridgers

Giovanni MitchellSkinheads 1979-1984: The Definitive Photographic Record by Derek Ridgers Walt WhitmanFollow ·19.2k

Walt WhitmanFollow ·19.2k Cole PowellFollow ·14.4k

Cole PowellFollow ·14.4k Don ColemanFollow ·19.5k

Don ColemanFollow ·19.5k Joseph ConradFollow ·8.9k

Joseph ConradFollow ·8.9k Clark BellFollow ·4.1k

Clark BellFollow ·4.1k F. Scott FitzgeraldFollow ·17.5k

F. Scott FitzgeraldFollow ·17.5k Roald DahlFollow ·3.6k

Roald DahlFollow ·3.6k Denzel HayesFollow ·12.1k

Denzel HayesFollow ·12.1k

Ivan Turgenev

Ivan Turgenev38 Art Made During The Pandemic Digitally Enhanced Art...

By [Author's Name] The year 2024 was a time...

F. Scott Fitzgerald

F. Scott FitzgeraldAmazing Cooking Guide To South Beach Diet: Your Culinary...

Embark on a...

Zachary Cox

Zachary CoxGeneral History of Chinese Film: A Journey Through Time...

Origins and...

Cristian Cox

Cristian CoxUnderstanding Antidepressants: An In-Depth Guide to...

Unleashing the Power of...

Jeremy Cook

Jeremy CookUnlock the NFT Revolution: A Comprehensive Guide for...

The world of Non-Fungible Tokens (NFTs) has...

Kevin Turner

Kevin TurnerSeneca and Roman Slavery Under Nero's Rule: An In-Depth...

During the reign of...

5 out of 5

| Language | : | English |

| File size | : | 7489 KB |

| Text-to-Speech | : | Enabled |

| Screen Reader | : | Supported |

| Enhanced typesetting | : | Enabled |

| Print length | : | 134 pages |